ZERGER RMS PLANT

RONESANS

-

PROJE ADI

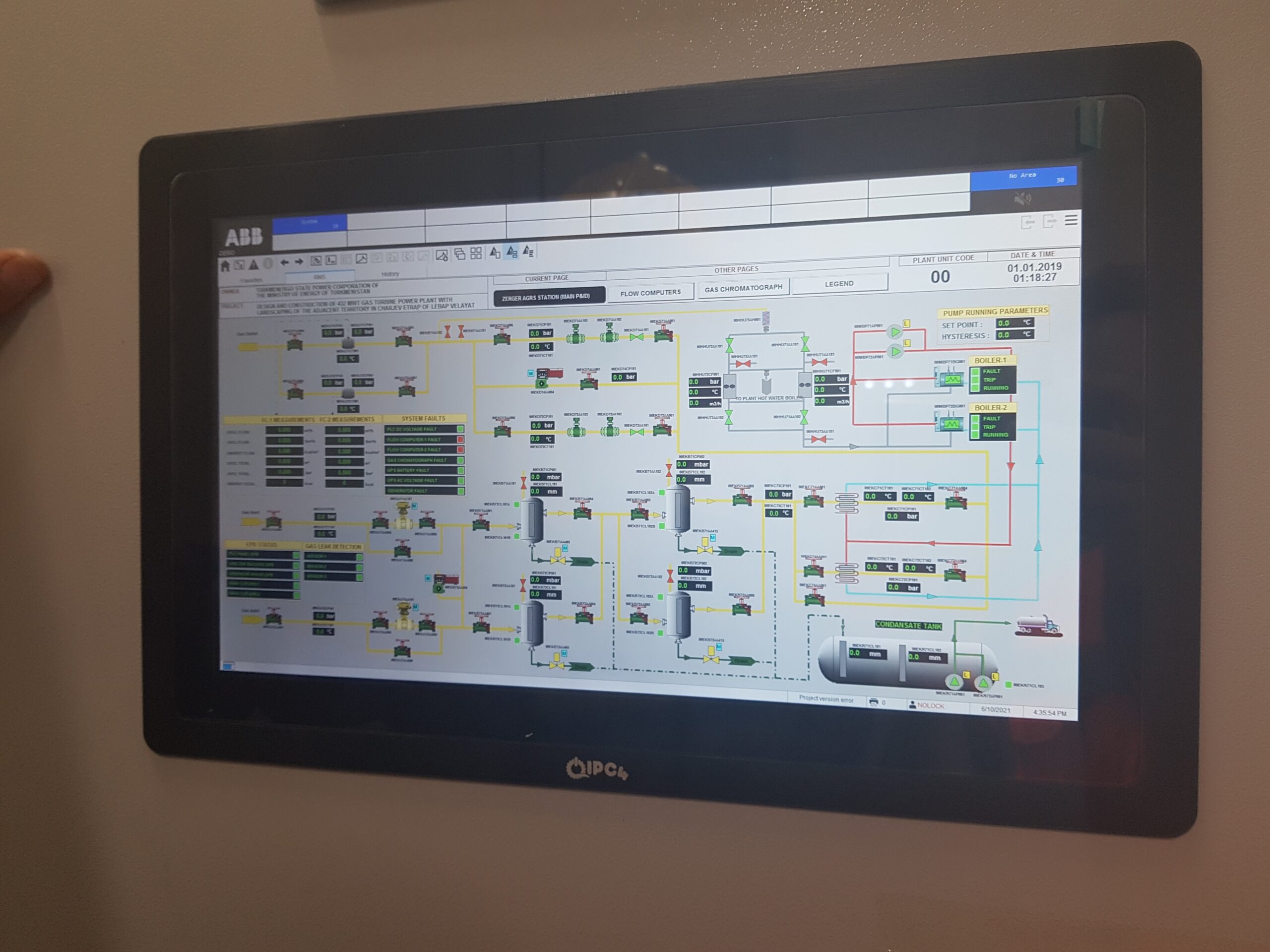

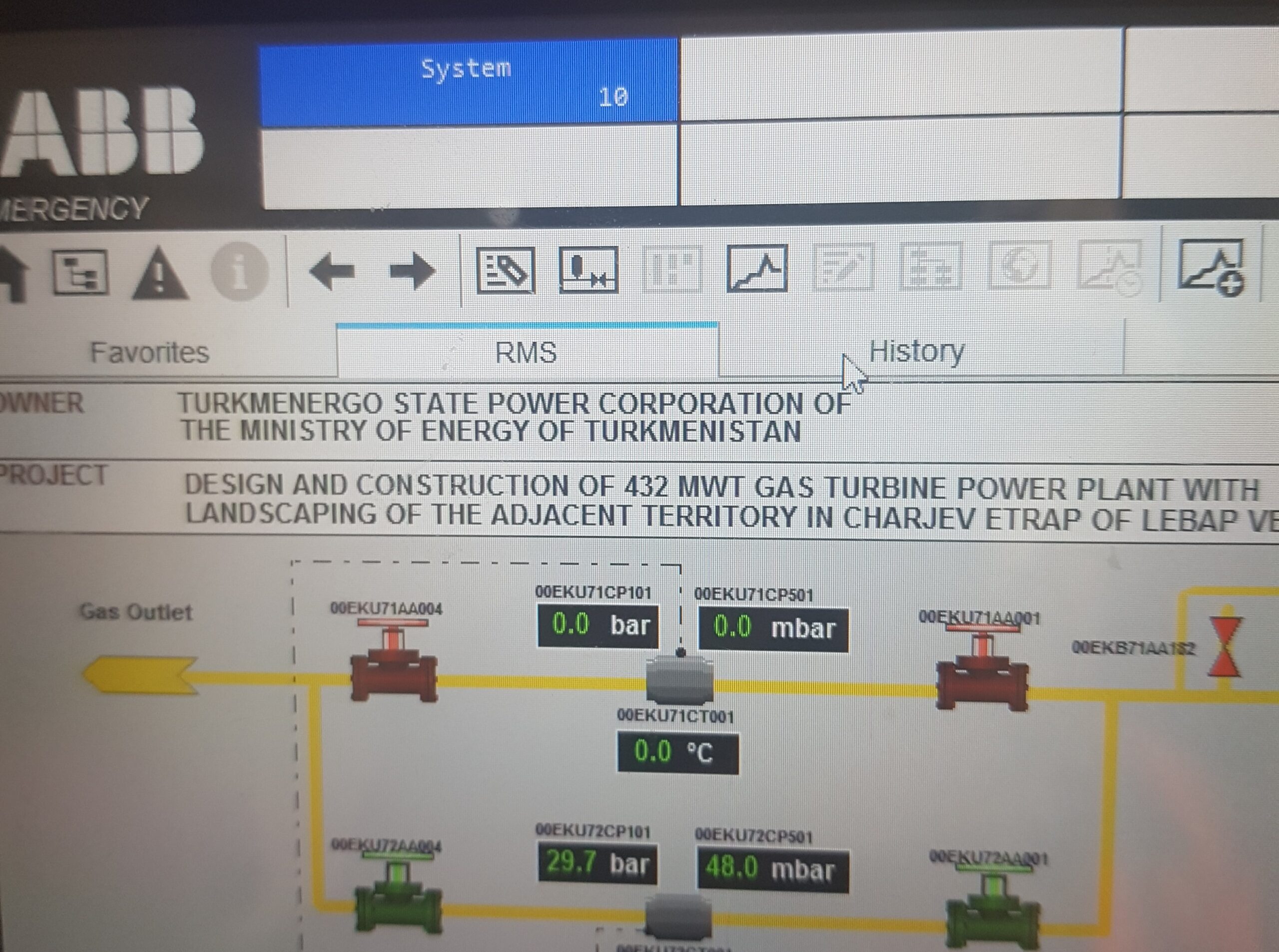

Zerger 432 MW Gas Turbine Power Plant AGRS Station Automation System

-

SECTOR

OIL & GAS

-

DATE OF COMPLETION2021-2022

-

SCOPE

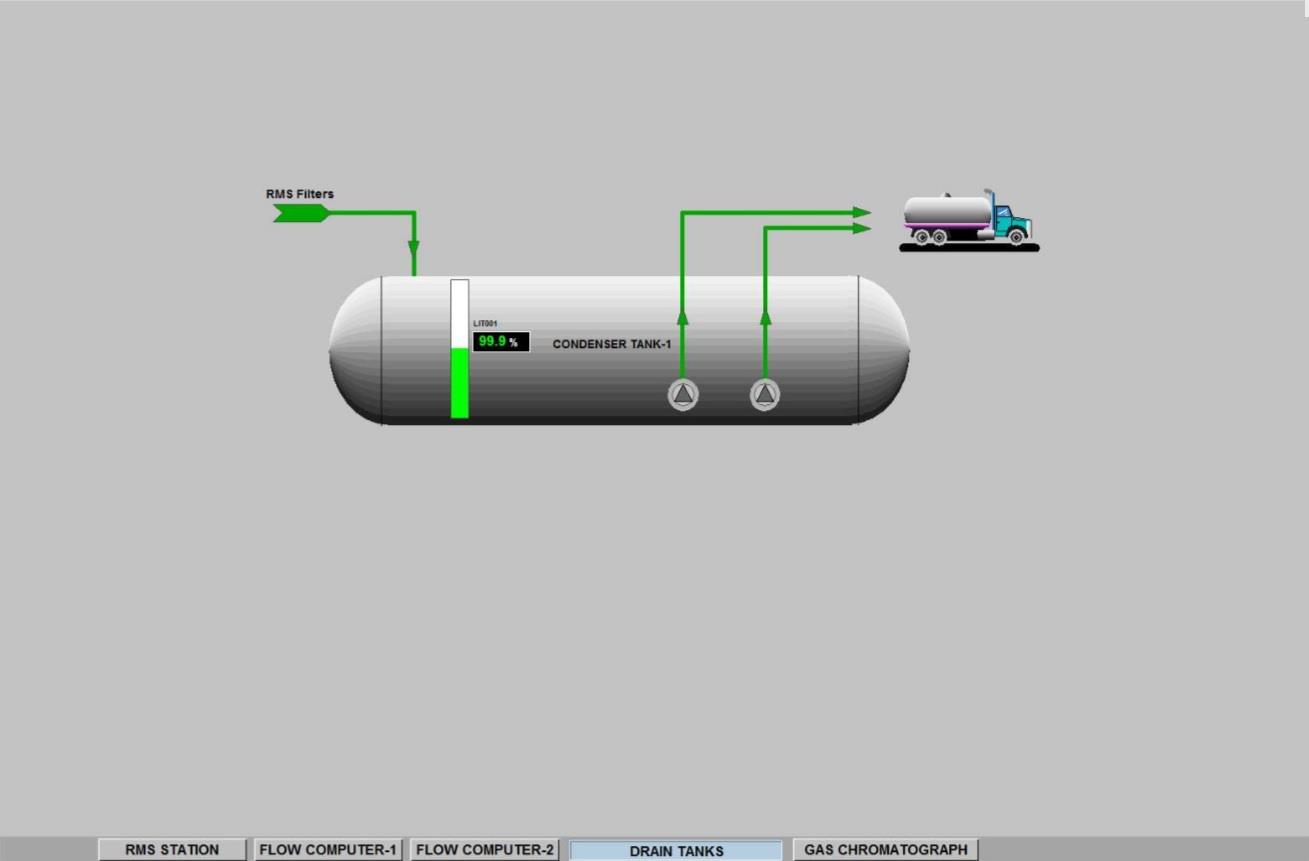

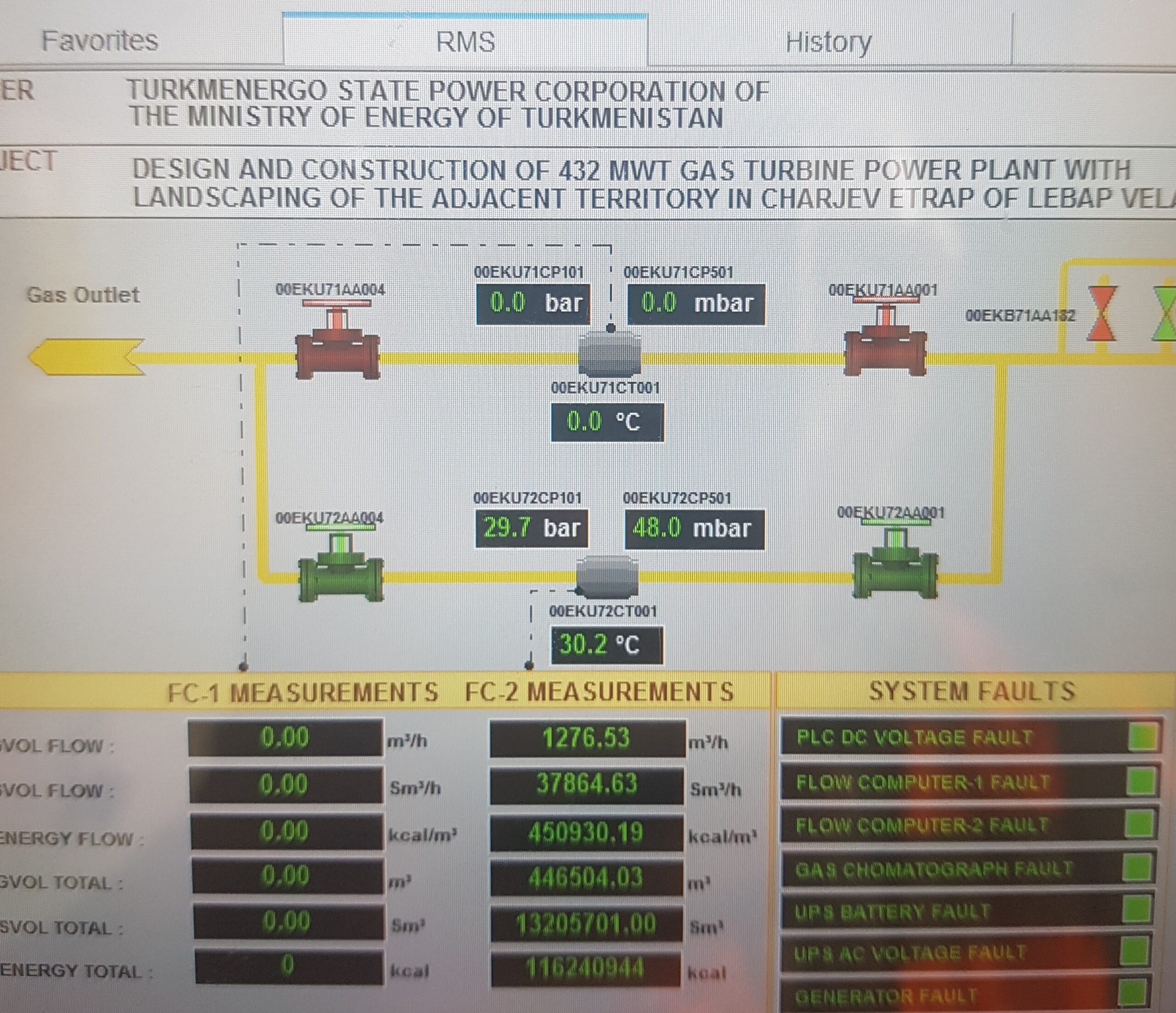

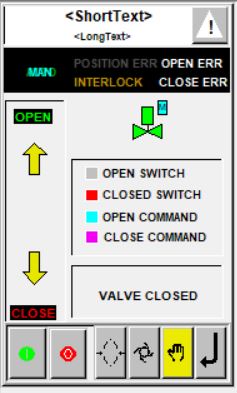

- Receiving relevant signals from mechanical equipment and devices within the natural gas combined cycle power plant at the RMS and preparing SCADA screens

- Manufacturing and supply of DCS Panel, MCC Panel, and UPS Distribution Panel

- EFT, cabling, panel connections, I/O, and software testing of panels

-

EXECUTION

Stations where natural gas pressure is regulated and measured according to operational needs are called RMS (Regulating Metering Station).

Our company provided robust solutions for the installation of automation and safety systems at all domestic and international facilities using the ABB Freelance 2019 Platform and S800 IO family.

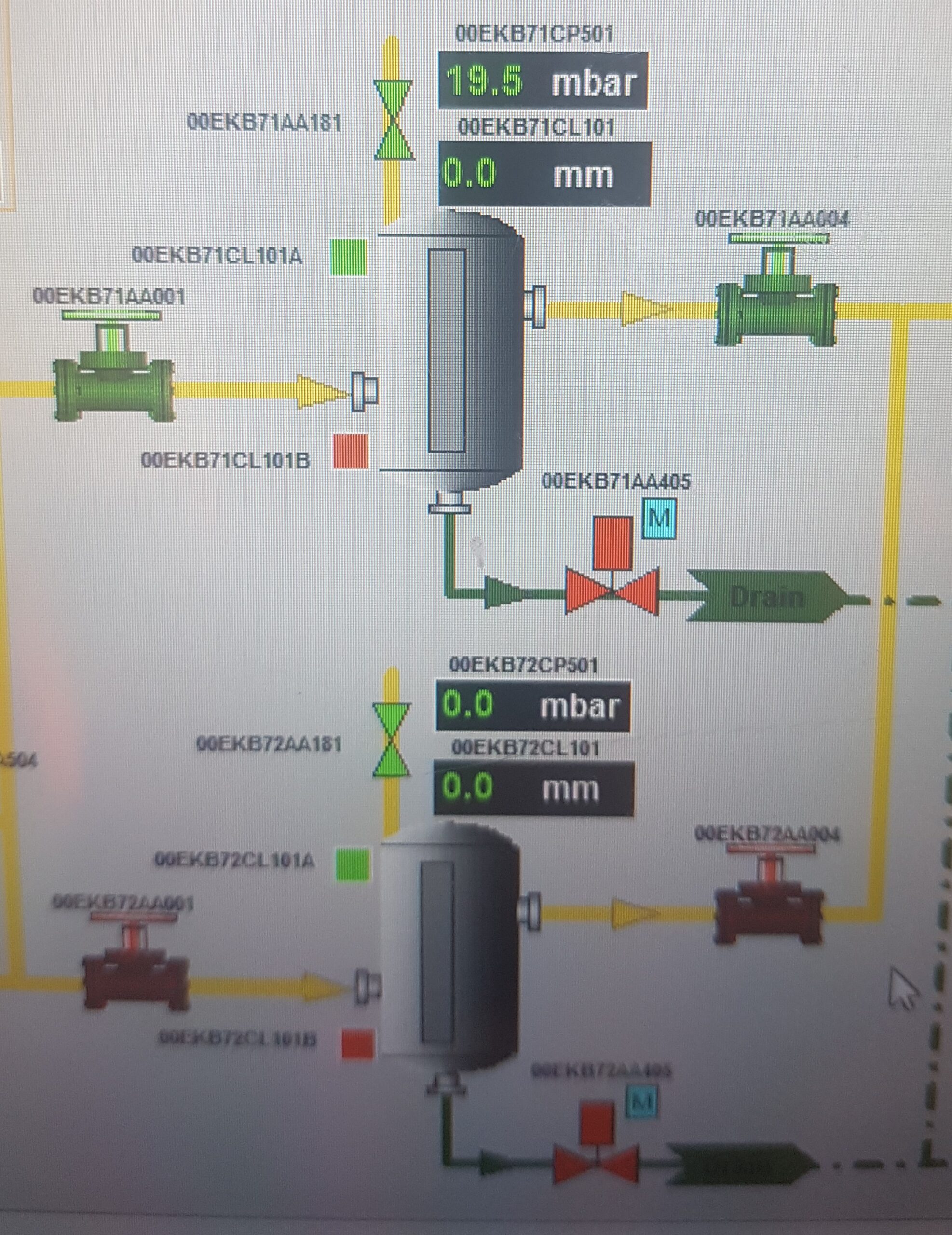

The main components of the system include: 2 redundant ABB AC900F DCS controllers, redundant remote IO modules, Elster FC1 Model Flow Computer, ABB NGC 8206 gas chromatograph, and transmitter equipment.

The flow computer transfers all data to the DCS via the Modbus protocol. Each gas detector records and displays the percentage of gas components. After the gas detector sends data to the DCS, the DCS forwards this data to the Flow Computer (FC).

The system includes three transmitters for pressure, differential pressure, and level. These measured values are sent through HART and 4-20mA analog signals.

The MCC Panel was manufactured as the electrical panel distributing main power to all equipment in the AGRS.

Additionally, the UPS DB Panel distributes critical load power in the systems, especially for the PLC Panel, Fire Alarm System, and CCTV systems.

All instrument cables were routed first to 13 junction boxes on-site, then to the PLC Panel. These junction boxes facilitated easy control of cabling systems.

REFERENCES

Contact

-

Phone

-

e-Mail

-

AddressKüçük Çamlıca Mah. Ümit Sok. No:10 Kat:1 Üsküdar İstanbul