Sungurlu OSB Pyrolysis Automation Control System Project

AK ENERJI

-

PROJECT NAME

Sungurlu OSB Pyrolysis Automation Control System Project

-

SECTORS

PETROL & GAS

-

DATE OF COMPLETION2021-2022

-

SCOPE

- SCADA system design including hardware, software, configuration, manufacturing, engineering, programming, testing, documentation, installation, and commissioning for auxiliary facilities

-

EXECUTION

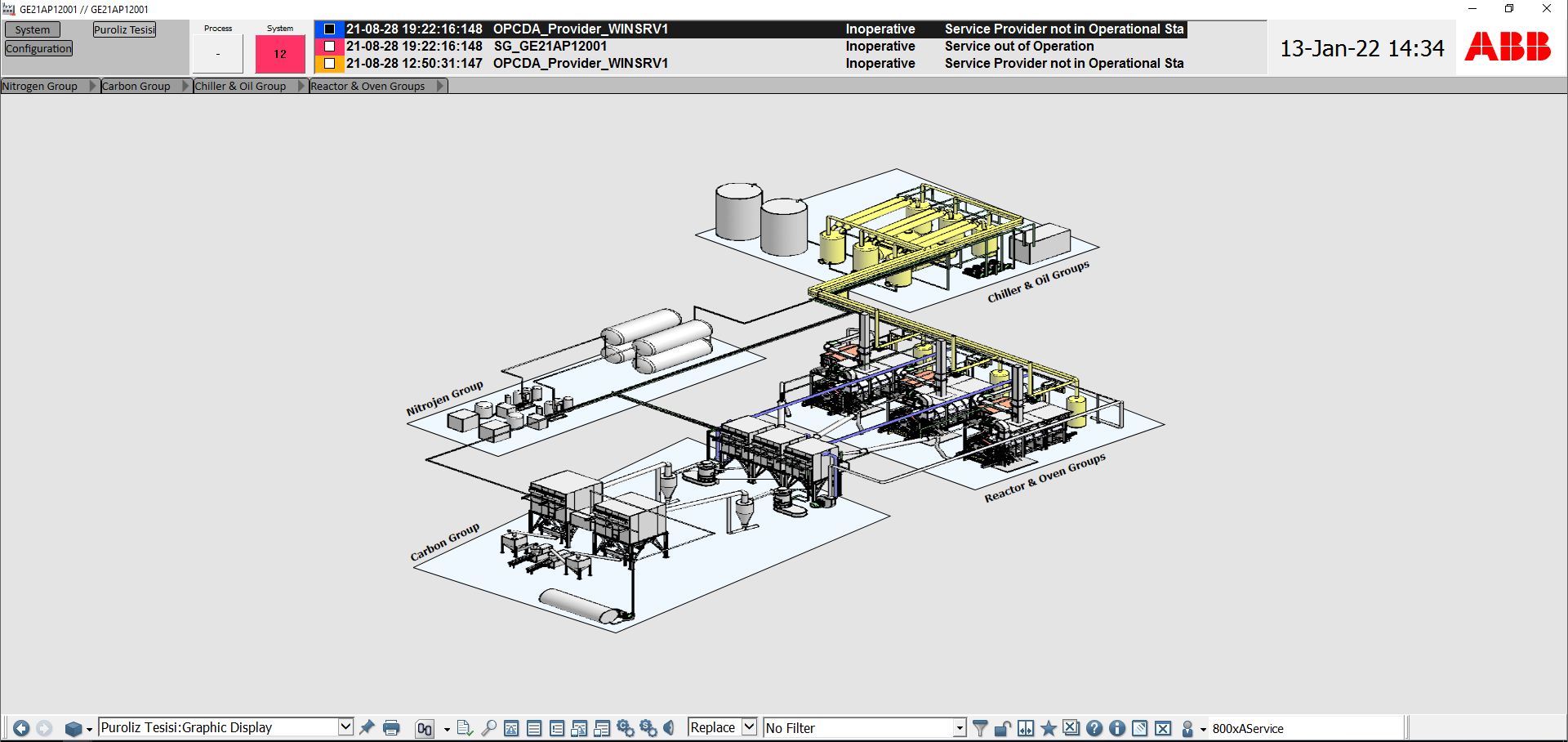

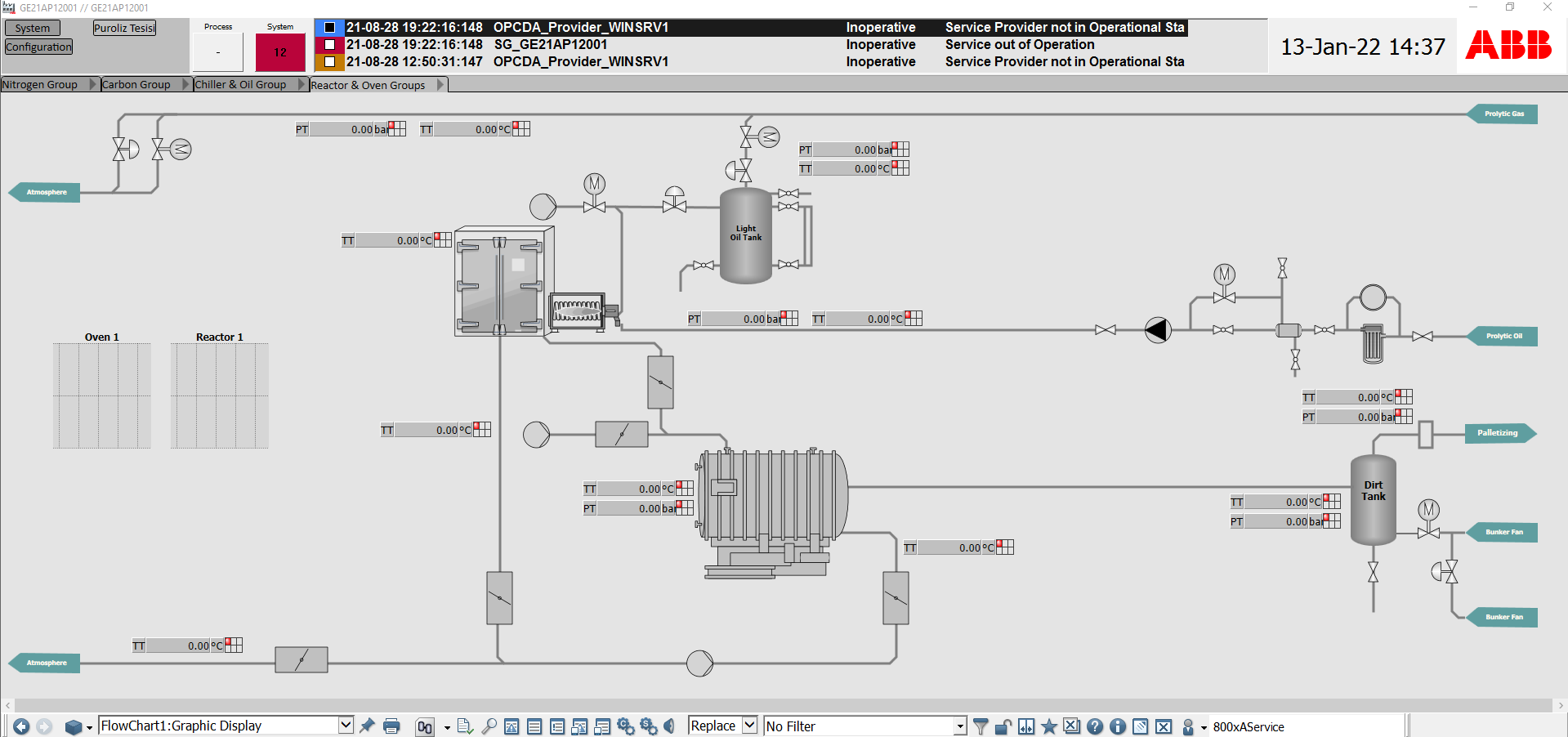

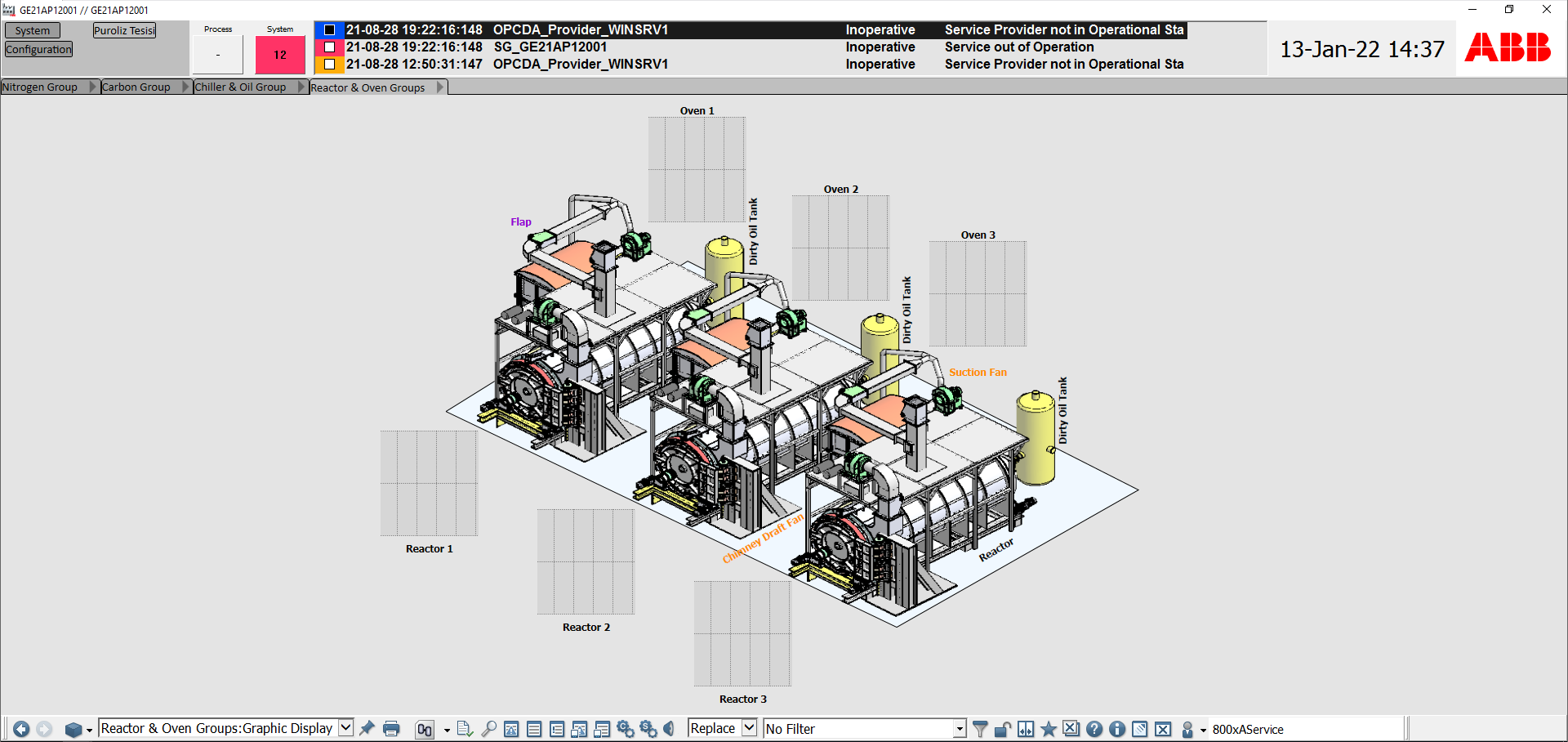

The complete monitoring, control, and supervision of the relevant process and electrical systems were carried out using modern and proven microprocessor-based Siemens PLC systems. These PLC systems interface with the DCS to enable remote normal control and monitoring from the CCR, making it possible to start and stop the systems both manually and automatically. Safe operating conditions must always be maintained.

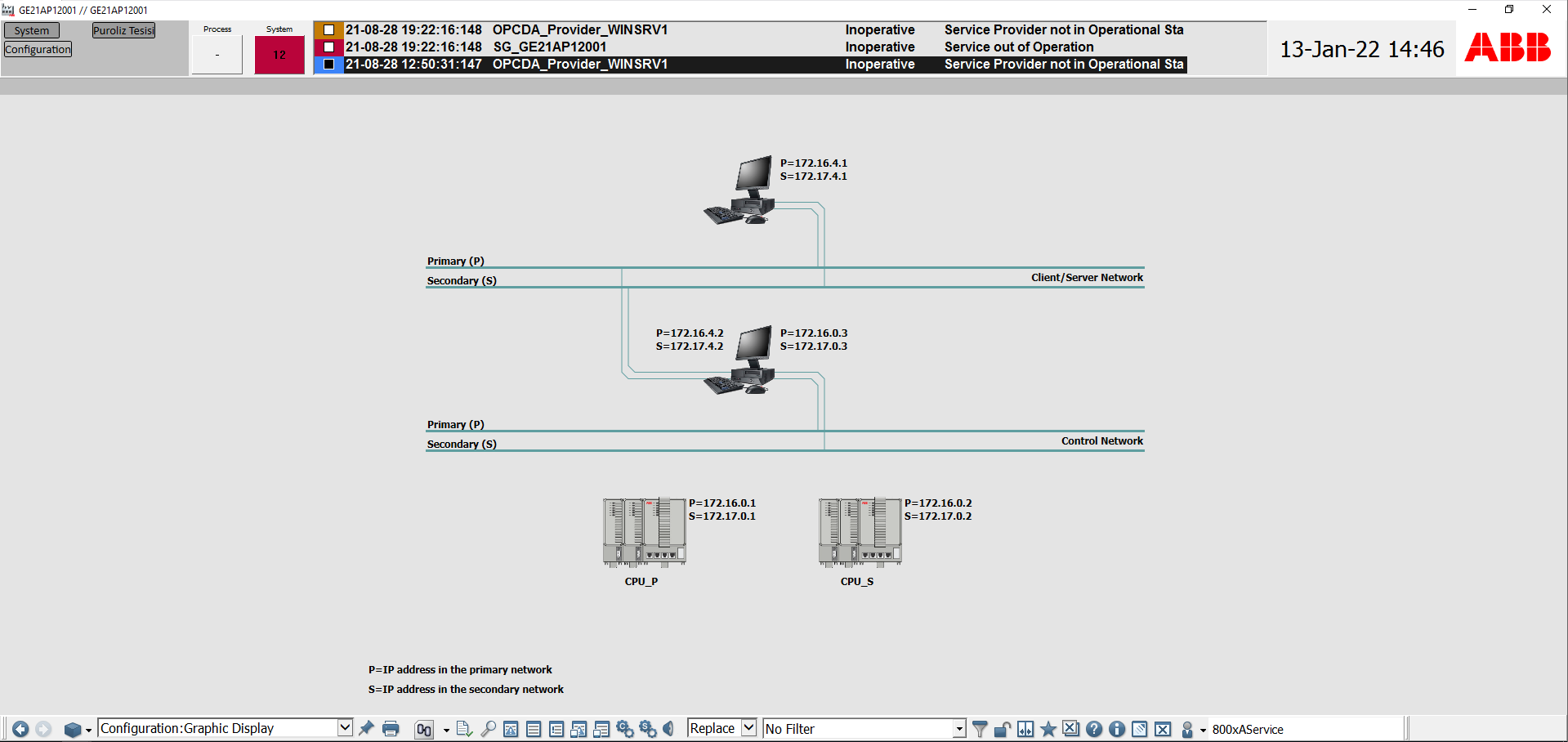

The PLC system includes redundant CPUs (hot redundancy and hot backup), power supplies, and networks. The successful supply and installation of interface devices (Ethernet hubs), media converters, and fiber optic cables for data communication between the PLC and DCS were completed.

In case of a power outage, a topology was established to keep control valves, actuators, dampers, etc., in a safe position. Position, measurement, and fault information of protection relays on the Medium Voltage cells were communicated to the system via an added RTU and displayed on the SCADA system.

The automation application was developed with the ABB Compact HMI 6.0.3 Platform and supports the AC500 IO family.

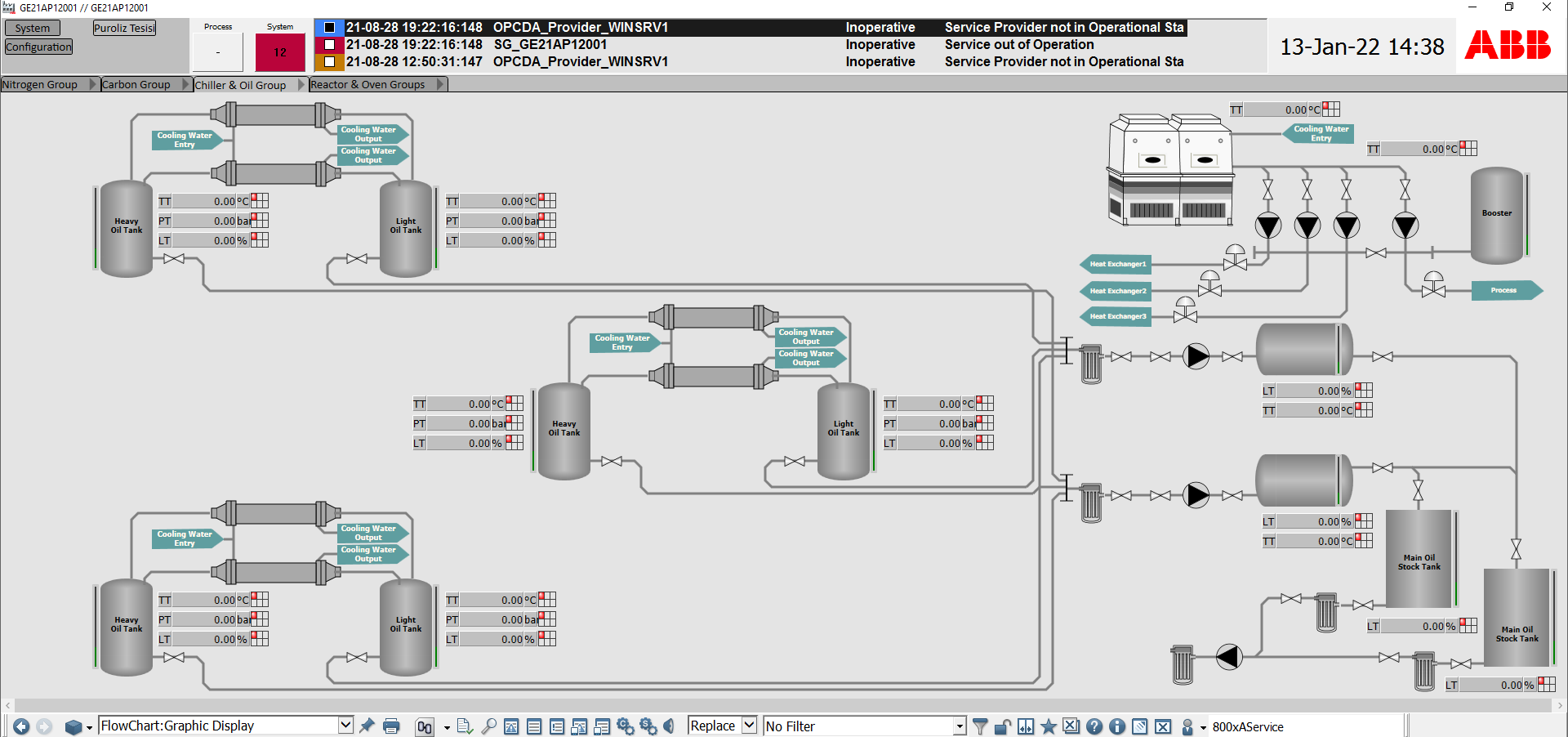

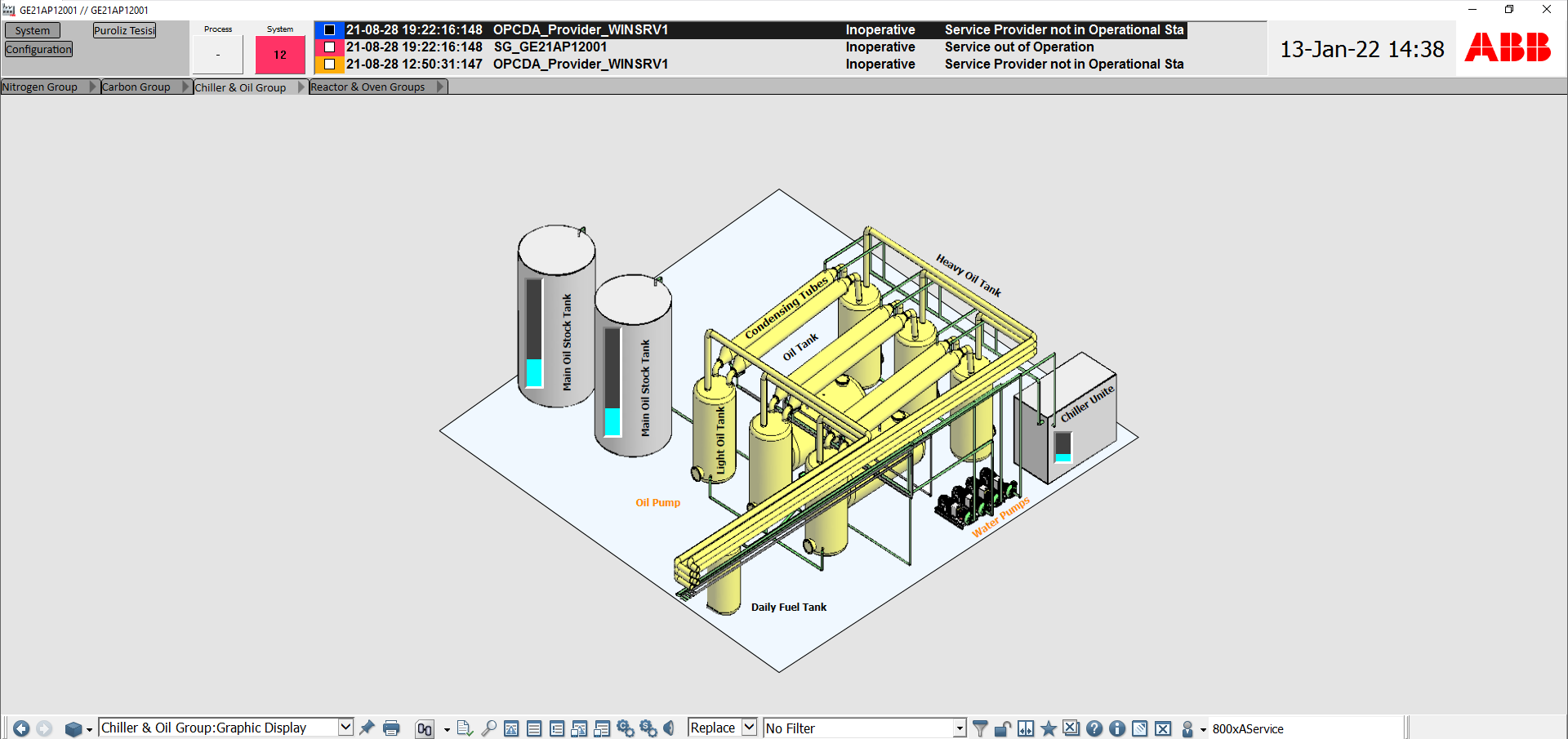

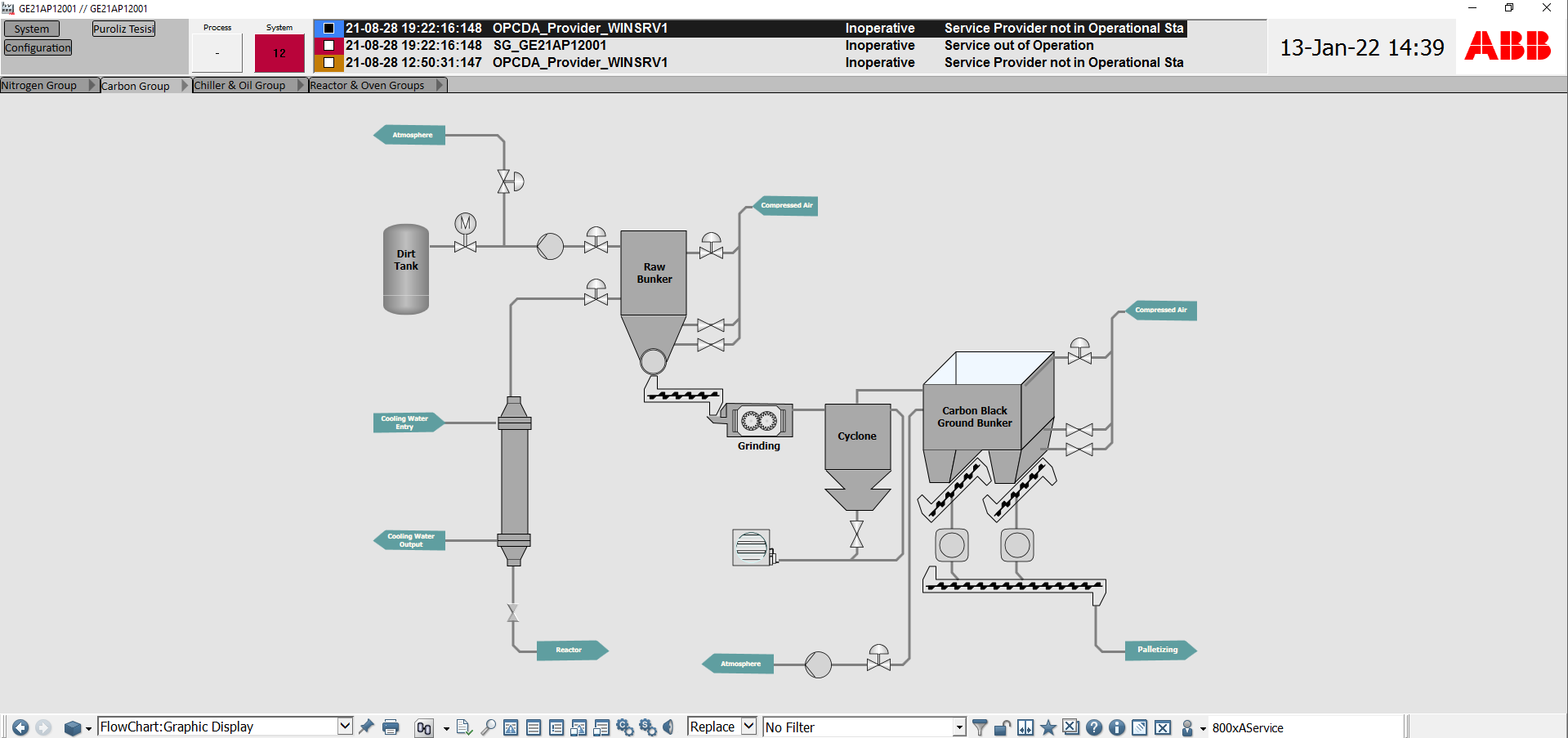

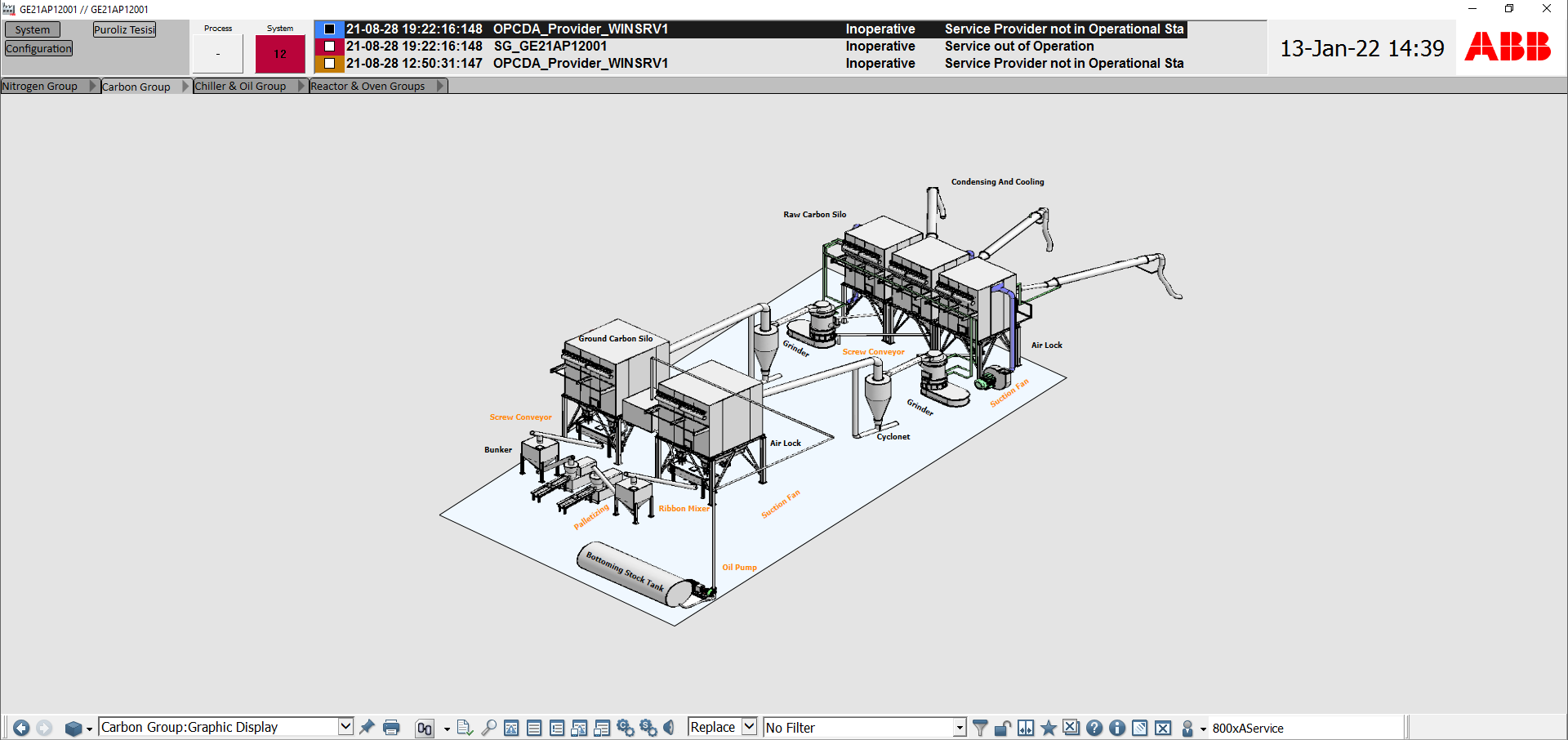

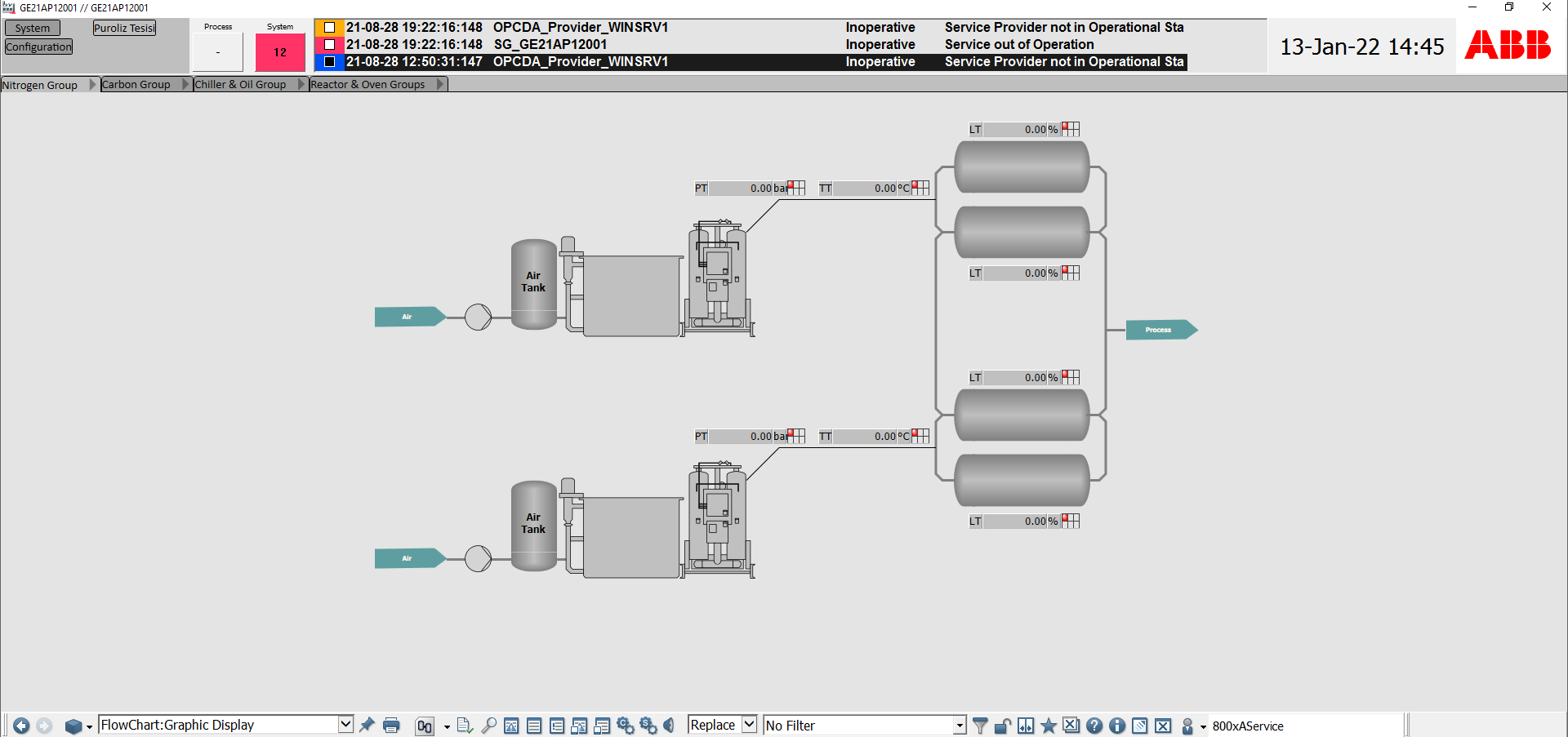

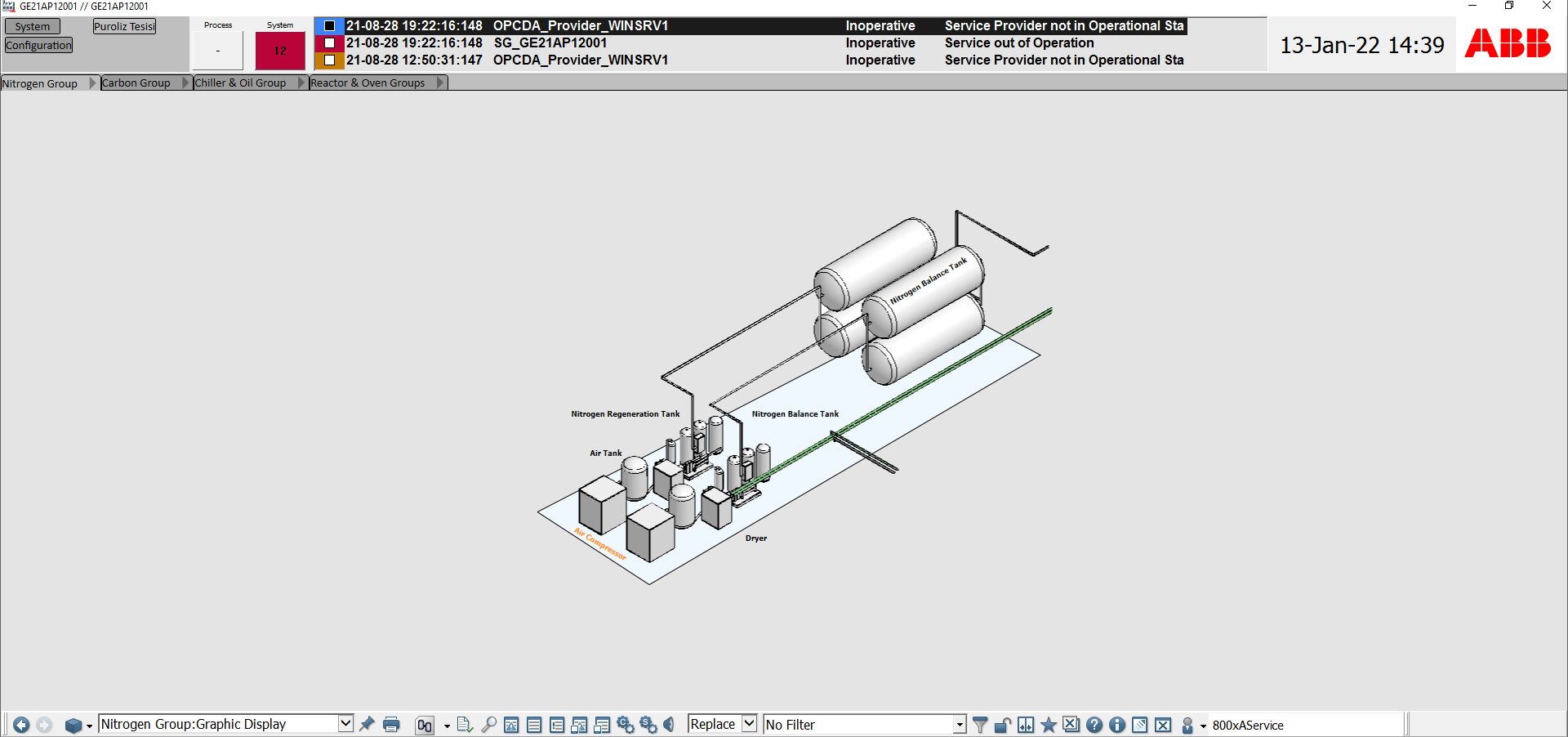

The HMI screens displayed at a minimum the following features for complete control and monitoring of the system:

– Viewing the status information of all drivers/systems, etc.

– Control and adjustment of system parameters

– Monitoring steps in sequential control applications

– Report generation

– Data recording

– Process graphical screen

– System view

– Real-time/historical trends

– Alarm management

REFERENCES

Contact

-

Phone

-

e-Mail

-

AddressKüçük Çamlıca Mah. Ümit Sok. No:10 Kat:1 Üsküdar İstanbul