Bazian RMS Plant

ÇALIK ENERJİ

-

PROJECT NAME

Bazian RMS Plant

-

SECTOR

OIL&GAS

-

DATE OF COMPLETION

2021-2022

-

SCOPE

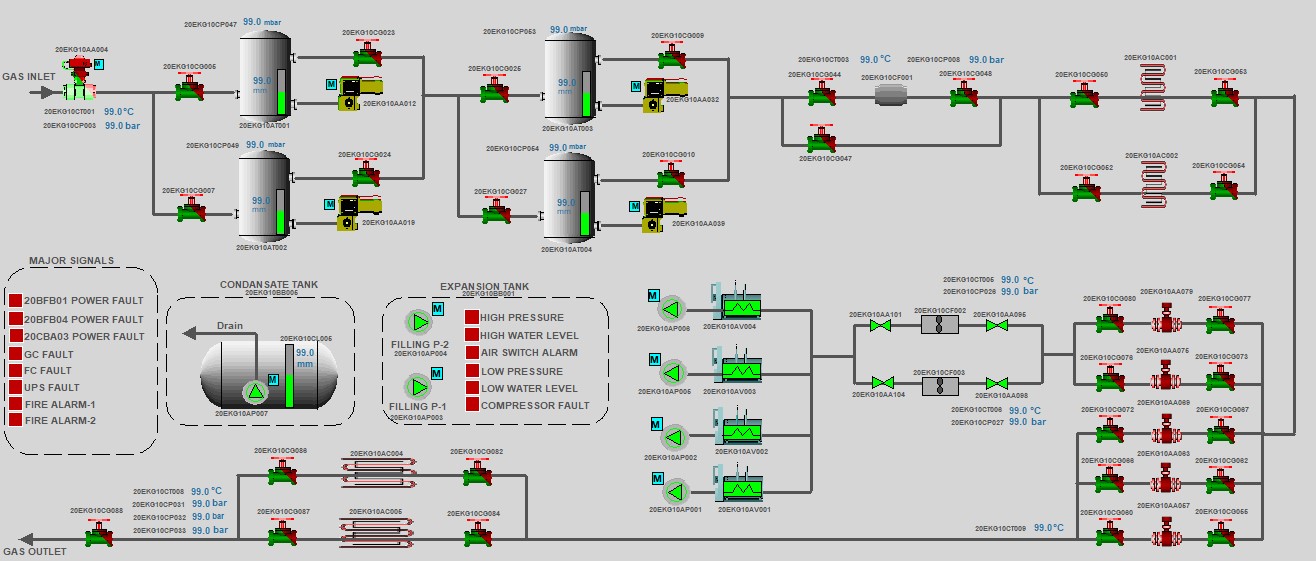

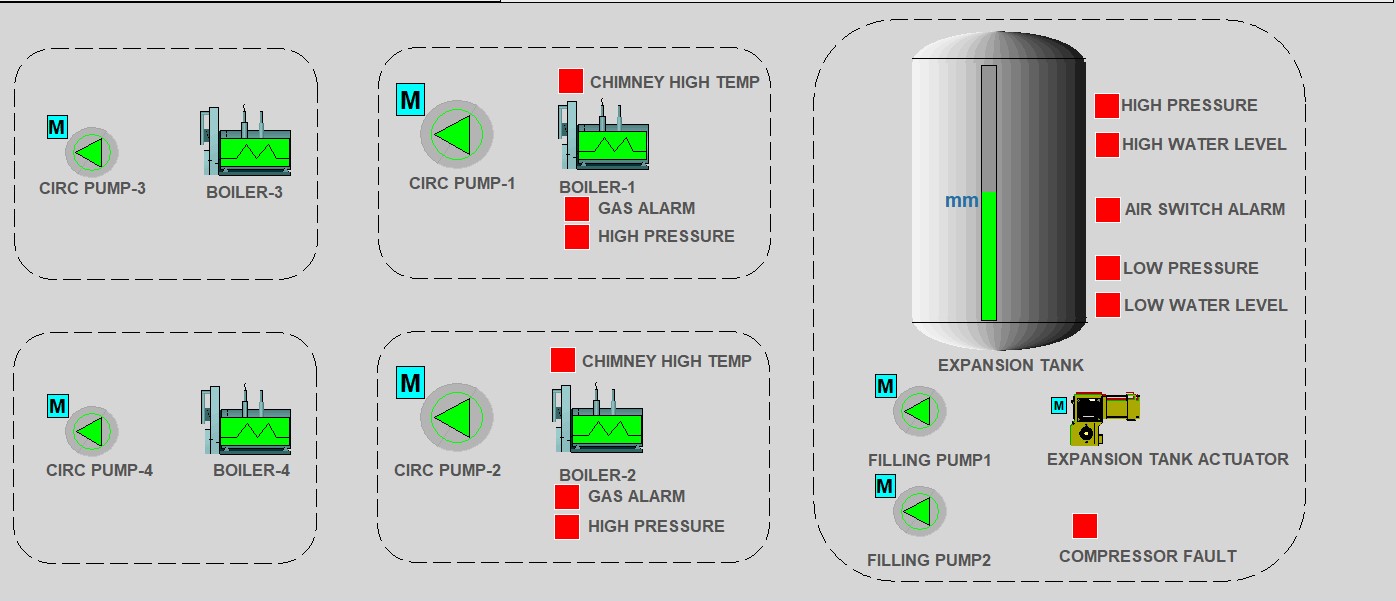

- Implementation of the PRMS Station Automation Project located in BAZIAN on the ABB Freelance Platform

- Providing natural gas supply to the gas turbines to be installed for a 40 MW capacity increase at the facility

- Design and supply of the electrical panel / MCC

- System operation and control with SCADA software and necessary equipment

- Definition of the required interface with the PLC package and the central control system (DCS)

-

EXECUTION

It is an automation application developed with the ABB Freelance Platform, supporting the S800 IO family. Communication is established through OPC and Modbus communication protocols with third-party systems.

Terminal blocks in the PLC cabinet are used for wired signals to the DCS. Communication and connection between the PLC and DCS are provided using fiber optic patch panels with FC-type connectors. For the flow computer, the patch panel – PLC communication protocol used is Modbus TCP-IP.

Flow meters with RS-232/485 MODBUS RTU communication ports provide diagnostic measurements and are integrated into the flow computer. Communication from PLC to DCS is via MODBUS TCP-IP protocol.

A PLC and HMI are used for the control and monitoring of the facility equipment. Operation, adjustment, automation, measurement, and necessary monitoring commands are used to control the equipment, ensuring the operation can be controlled automatically, semi-automatically, or, if necessary, fully manually.

REFERENCES

Contact

-

Phone

-

e-Mail

-

AddressKüçük Çamlıca Mah. Ümit Sok. No:10 Kat:1 Üsküdar İstanbul